TheJetWorkshop

A small engineering company specialising in designing and producing miniature gas turbine engines.

Makers and suppliers of Xicoy "X" Series Miniature Jet Engines

We are principally a design-and-build workshop, equipped to manufacture miniature gas turbine engines from raw components, principally the small engines of the Xicoy X45, X60 and X95 for the model market.

The "X" Series jet engines are licensed from Xicoy Electronica SL, Spain by kind permission of Gaspar Espiell.

We are the only company worldwide outside Xicoy, licensed and approved to build and retail Xicoy engines.

TheJetWorkshop also produces its own jet engine designs and undertakes commissions for one-off or experimental gas turbine engines.

TheJetWorkshop has inhouse design capability through SolidWorks Professional 3D and Autocad drafting. 3D models are created to produce printed wax metal castings for rapid prototyping and small scale production.

TheJetWorkshop is run by Mike Murphy, ex RAF Ground Support Fitter (Vulcan era) with 24years experience in miniature jet engine design and production.

We welcome orders/enquiries via our email thejetworkshop@gmail.com or click the email button.

Xicoy "X" Series Evolution/Revolution

Xicoy "X" Series Miniature Jets

Key Features

Xicoy Engine Specifications

X45

Thrust 45N/10Lb RPM 60k (idle) to 225k (max) - adjustable 25-45N Idle thrust 1.8N Weight 395g (engine only), 470g (all except battery) Dia 60mm Length 165mm Package includes: X45 Engine, inc FOD screen Fuel pump Cable set Piping and fuel filter USB card full instructions, plus A5 paper quick start guide. Hub Lite and multi-colour touchscreen display, or Compact Hub incorporating built-in black/white display. Comes in smart printed white presentation box, inside a sturdy cardboard transit box. Please retain these in case of engine return. email: thejetworkshop@gmail.com for latest pricing and ordering

X60

Thrust 60N/13.2Lb RPM 55k (idle) to 190k (max) - adjustable 35-60N Idle thrust 2.5N Weight 451g (engine only), 526g (all except battery) Dia 68mm Length 159mm Package includes: X60 Engine, inc FOD screen Fuel pump Cable set Piping and fuel filter USB card full instructions, plus A5 paper quick start guide. Hub Lite and multi-colour touchscreen display, or Compact Hub incorporating built-in black/white display. Comes in smart printed white presentation box, inside a sturdy cardboard transit box. Please retain these in case of engine return. email: thejetworkshop@gmail.com for latest pricing and ordering

X95

Thrust 95N/21Lb RPM 45k (idle) to 176k (max) - adjustable 45-95N Idle thrust 3.5N Weight 706g (engine only), 888g (all except battery) Dia 76mm Length 183mm Package includes: X95 Engine, inc FOD screen Fuel pump Cable set Piping and fuel filter USB card full instructions, plus A5 paper quick start guide. Hub Lite and multi-colour touchscreen display, or Compact Hub incorporating built-in black/white display. Comes in smart printed white presentation box, inside a sturdy cardboard transit box. Please retain these in case of engine return. email: thejetworkshop@gmail.com for latest pricing and ordering

Options & Extras

Ordering

How do I place an order?

Engines we build X45/X60/X95 are usually in stock for immediate delivery which means you could receive within two days in the UK. We do sometimes have used/recon' engines available, just ask!

We are authorised by Xicoy to supply only UK customers.

Payments must be cleared before shipping.

Payment is via bank transfer or credit card. Both via online invoice, we will send you a breakdown of your order with a link to pay online, quick and easy.

Shipping is usually next-day insured, you can indicate if there is a preferred day when you are in to receive your engine, just let us know and we will arrange it. We can do "brown wrappers" if your parcel needs a disguise.....!!

I live nearby, can I collect?

We are easy to find, postcode DN6 7ER, just off the northbound A1M J38 or the Doncaster/Wakefield road A635.

I know nothing about jet engines, can you help?

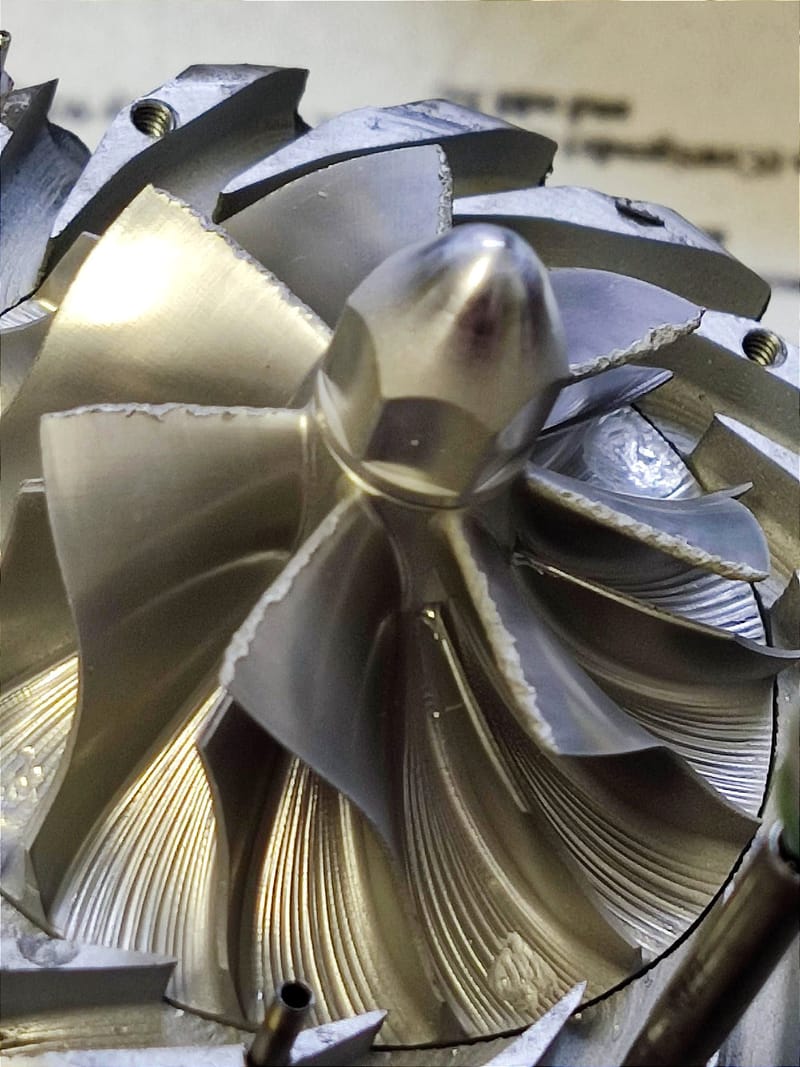

For those picking up an engine in person, we are happy to spend a little time in the workshop introducing how the engine is made and what the internal parts look like and what they do.

Many bring a friend too and that's no problem, just be aware the workshop is quite small, not enough room for a crowd!!

We have an indoor test cell where engines can be run and you can see how to set up the engine and what the various settings do and have a go at running an engine yourself.

Visits are always by prior appointment as its not practical when we are building, and note are available for those purchasing an engine only.

Questions 1

What's the difference between Lite and Compact Package?

Lite package uses a small stamp size (42x24mm) shrink wrapped module which we call the "HUB", which the engine cable, battery, fuel pump and if you have one - the telemetry adapter, plus an external colour ECU display. This full colour graphics display has a touch sensitive screen which is bright and small enough to be mounted in the model, or can be unplugged when not required (its not needed for running).

As the colour display is quite expensive, it's useful that you don't have to have it permanently fixed in the model. The colour display also records the last 66minutes of operation and has a micro USB slot to install a micro USB card to offload the data to be examined on a PC easily, as it uses basic comma separated values that can be read in a spreadsheet.

Compact package combines the function of the HUB and display to a single unit. It's a boxed (35 x 46mm) black and white text type display with click action buttons. This eliminates the need to have a plug-in separate display but means you have to put it somewhere you can get your fingers to and it stays in the model all the time. The battery and engine also plug into this as does the fuel pump, and you can add the Xicoy telemetry adapter.

As this screen does not have any colour graphics or data recording it is the cheaper option.

You can add either type display later as an option if you choose.

I have two models, can I swap the one engine between them?

We saved you the hassle of listing the requirements by calling the complete set a "2nd Install Kit" which you can buy anytime and contains all the bits needed to fit out a 2nd model ready for you to swap the engine over.

The engine will control the pump just the same and there is no additional setting up to do when swapping them over, just prime the fuel tio the engine and it will take care of everything else. You can even have a different setup, you don't need to keep to Compact or Lite as you had in the 1st model.

Just be sure to order the 2nd Install to suit your correct engine size, simples!

What's so special about the "X" Series fuel pump?

The pump consist of a brushless outrunner type motor driving tiny gears, connected to a dedicated electronic controller, all squeezed within the tiny pump casing. It receives a command signal from the ECU in the form of a serial digital data stream, not an analogue voltage.

As soon as you connect it to the ECU, the ECU identifies it and if it is the wrong pump for the engine, it will refuse to drive it and will send an error message.

If you try to drive it with a regular ESC type control to prime or cycle it, you will blow the electronics inside immediately!!

The three connections are +, - and a 32bit serial data stream, NOT three wires of a typical 3-phase motor.

Make sure the plug is pushed fully home or it may show "pump not found

Can I derate the engine for 1st flights, the model is a bit fast and only 30N recommended?

In the RUN menu the MAX RPM reading also shows the Full Power thrust in N and in pounds (L) for that particular rpm.

If you dab the "-" button you can reduce the Max rpms and see the corresponding reduced maximum power the engine will produce. So its a cinch to reduce from say 95N to 80N without having to do any mental gymnastics to work out what the new rpm setting needs to be, just dab the button until you see the power setting you want.

The ECU will rescale the rpm range so 100% throttle will now equal the new maximum you have set.

Later on when you need, you can adjust it back up to maximum or anywhere in between by pressing the "+" button as you require.

Questions 2

What battery can I use?

A 2-cell LiFe is not enough volts and will not work.

It is technically ok to use a 3-cell LiFe battery but a 3-cell LiPo is too high a voltage and the electronics will struggle with the higher power dissipation on the circuit board, even if it does work.

For best results stick with the 2-cell LiPo, at least 2000mAh+ or more, and at least 25C rating.

Always disconnect the battery from the ECU for charging.

Powering up the receiver to the ECU will also close a switch in the Hub to turn on the ECU battery supply. Equally the ECU will retain the battery power until the engine has completed its cooldown cycle after running, even if the receiver has been turned off.

So it is not needed to keep the receiver on until the engine has finished cooling, it will turn off automatically.

What is the recommended fuel and oil for my turbine?

The engine can use pump diesel where kerosene is not available but it does not run as sweetly and the smell is dreadful.

In the START menu there is a switch for KERO / DIESEL which you can use to switch fuels. The engine default fuel setting is "KERO".

Changing the fuel setting over ripples a range of changes through the ECU automatically to best optimise the ECU to running on the fuel selected, so you don't need to remember and work through changing all the settings yourself.

But in all cases, Kero is the preferred fuel and definitely not mucky heating oil someone is getting rid of....!

If you have a fuel for other jets you run, which has 5% oil mixed, you can also use this, no need to keep two lots of fuel. The different oil content is so small it make no difference to running or engine life.

OIL

In thejetworkshop we use red coloured Carlube 2-stroke XL oil, as sold in stores such as B&Q, Halfords etc, mix at 4%. The Power Model Jet Oil oil sold by Deluxe Materials also works well and is recommended by Xicoy - I tested it when I was there!

How do I prime a new fuel system?

New systems always have a few small bits and particles, so don't connect the engine immediatly, leave the engine end of the fuel feed open and hold it into a jar or paper towel. Connect ECU battery and turn on the transmitter and receiver (make sure trim and stick is low).

Be sure the pump plug is correctly orientated (see label) and pushed fully home, it goes in quite a way and can be a bit tight sometimes.

Using the display, enter the INFO menu and proceed to the PUMP PRIME screen. Press the "+" button to start the pump running slowly and watch the fuel moving gently from tank to engine. Let it dribble for a few second to clear all the loose bits then turn off pump ("-" button) and connect to engine.

You are now ready to do your start. Give the fuel filter a good shake during the starting to clear it of bubbles, same if you have an air trap. Don't use felt clunk in tank, it will release bits of fluff which always seem to find their way into the pump and strangle the tiny gears!

What is the best procedure for turning off the engine?

The best procedure for shutdown is after you have completed all your taxiing etc, to restrain the model and gently rev the engine to about 1/3rd throttle and hold it for a count of 10 slowly, then quickly bring the trim to zero, followed by the throttle stick. This ensures the engine is running at its coolest and with a decent flow of lubrication through the bearings at the point you shut it off.

The engine at idle supplies almost no lube to the bearings, and runs a lot hotter, so leaving it to idle for extended times is not good for the engine.

Always rev to 1/3rd for 10 secs before shutdown, your engine will thank you!!

Service and Repair

Don't worry!!

With any flying model there is also the possibility of mishaps, bad landings, problems with the model structure or loss of control resulting in a crash that may result in damage to your engine. Your Xicoy engine can always be repaired however bad it looks. As we are the manufacturer of your turbine we have ALL the parts needed to rebuild it to as-new or if you prefer to have it just operational to keep costs down. If you find your engine performance is deteriorating or just not behaving as sweet as it was at new, can be just wear and tear or something more. We are very happy to look at this and let you know if your engine needs something doing or suggest an upgrade or service. Please note that it is a condition of the warranty that the engine is maintained in good order, serviced on time etc. So if your engine develops a fault, starts being very noisy etc, then please get in touch and have it looked at. We offer: Crash repair & restoration Fault rectification General servicing Hardware upgrades Software and electronic upgrades Warranty work Remember - we only charge for doing, not for looking, plus the travelling back and forth.

Learn MoreWarranty

Over the years, in addition to our work with the Xicoy and the "X" series engines, I have assisted other people and organisations to develop a special purpose idea into a fully operational gas turbine engine.

Almost all of these have special quirks, needing measuring ports for educational or research purposes, odd sizes and power outputs, aero type thrust engines, shaft power takeoffs for driven loads, odd fuels and gases, the list goes on and on. The common theme in all is they are not usually available off-the-shelf.

At TheJetWorkshop we have the capability to design and produce bespoke turbine engines for clients as one-off proof of concept or small scale production, so if you have a special requirement and would like to see it brought to life, either as a 3D modelled design or developed to a fully functional prototype, then talk to us and let's see if we can help.

Email thejetworkshop@gmail.com in the first instance, or call Mike on 07592861640 to talk through your idea and see what we can do for you.